Menu

5.0 Stars - 12 Reviews

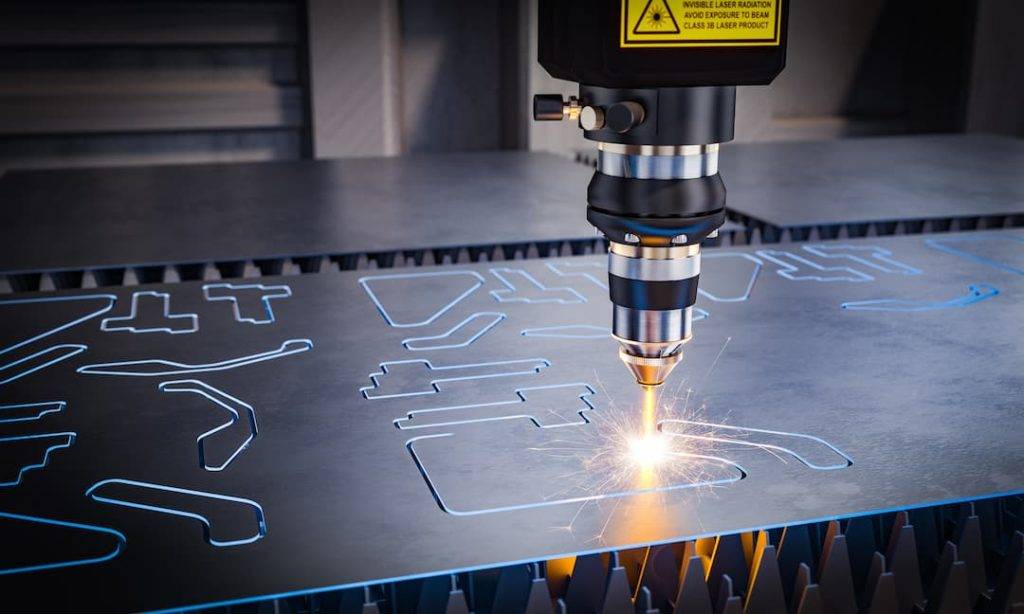

Laser cutting is a technique that’s been used for many years. Previously, only simple cuts could be achieved with lasers. However, recent developments in technology now allow us to create intricate designs, including the parts needed to create bespoke vehicles.

Lasers offer a level of precision that can rarely be matched. They can produce results quickly. As the technology continues to develop, cuts become more accurate. A better cut results in fewer refinements needed at the assembly stage. This saves time and ensures that the end result of your automotive build has a flawless finish.

Because laser cutting is done by machine, it can produce consistent parts in a variety of materials with great success. Once a cut has been made that you’re satisfied with, it can be produced in plastic, fabric, glass, rubber or your desired metal. Nearly every modern car will have at least some of its components made using lasers.

The most obvious may be the metal parts. However, there are a lot of components which will benefit from laser cutting. Everything from the seatbelts to the leather seats can be cut using lasers. This produces a seamless finish all-around, and saves a huge amount of time compared to other methods. An additional benefit is that any pieces that you choose to have cut with lasers can be produced en-masse with a consistent shape and finish. This is great if you’re creating a new product that you intend to sell to a wide audience.

We’re passionate about all things automotive. If you’ve got an idea for a bespoke build, speak to us about our tailored cutting service. We can produce one-of-a-kind pieces as well as multiple consistent cuts to create an entire fleet.

© 2022 - Search4local Ltd. The content of this website is owned by us and our client; copying of any content (including images) without our consent is in breach of our Terms & Conditions. | All rights Reserved